PAT testing is a common approach undertaken by employers to ensure the safety of their employees. Providing a safe workspace to work is necessary to build morale and improve the productivity of your business. It might seem like a regular inspection of your electrical appliances, but there is more to that.

A sudden defect in any electrical equipment can lead to several issues within the workspace. This can also affect the regular course of business. For such reasons, employers must be aware of the myths so they develop an effective course of action to keep their electrical systems in check. Here are some common myths that you should not believe them.

Importance of PAT test

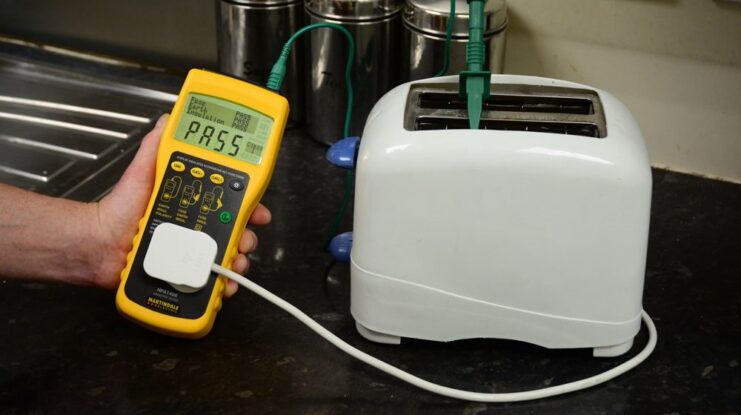

PAT or Portable Appliance Testing is an approach used to determine any defects in electrical systems and devices. This can determine the efficiency of machinery and equipment that runs on electricity. The need for PAT test is used as a safety measure in workspaces and homes.

Electrical appliances and equipment often malfunction or get internal or external damage over time. This can lead to mishaps or hazards and the best way to prevent this is inspection and test after regular intervals.

To perform this test you don’t need anyone with expertise in working with electrical appliances. The need for this test can provide employers with regular updates and feedback on the functioning of the electrical systems. This will also prevent delays in performance and carry out business operations smoothly.

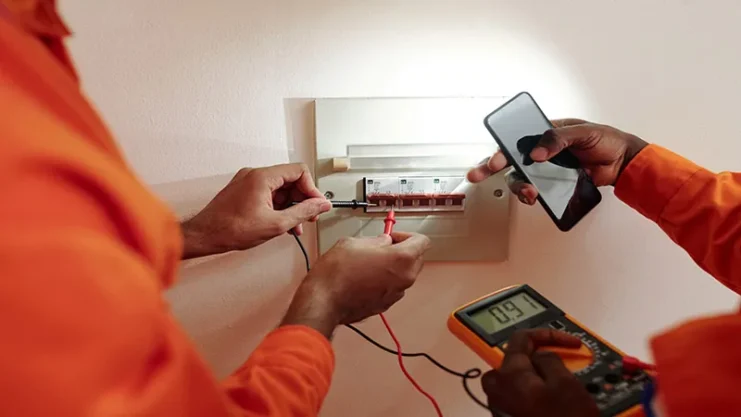

Some tests can detect damage with a visual inspection. Other internal damages may require tools and equipment to properly examine the electrical systems. This test is important for both businesses and households. This test is used in almost every industry by both small and big corporations after regular intervals.

Common Myths and Misconceptions about PAT Testing

1. Performing PAT Test Every 12 Months is Compulsory

People often claim that performing a PAT test every 12 months is compulsory. It depends on the type of electrical appliances installed in the office premises. Other factors determine the need and need for PAT testing. This involves malfunctioning electrical equipment or any damage to the wires or socket.

Damage to the outer parts of the electrical appliances can be visible from the outside. Conduct PAT tests to prevent further damage and ensure safety within office premises. If there are no major issues then it’s best to take a two-year gap before booking the next PAT test appointment. Click on this link to avail yourself of reliable and professional PAT testing services right at your fingertips.

2. PAT Testing is a Legal Obligation

There has been a lot of confusion related to the legality of PAT testing. It is a common misconception that PAT testing is a legal obligation. This is a myth, and companies or homeowners have no legal need to perform this test. But, inspecting the electrical equipment can prevent hazards and mishaps in workspaces.

Taking precautionary measures to ensure the safety of electrical appliances is essential. Employers must consider this approach to measure the risk factors within the workspace. This will also provide the safety of the employees. Homeowners can also keep their electrical appliances in check and prevent any danger.

3. Only a Qualified Person can Perform this Test

It is a misconception that only a qualified professional can test electrical appliances. PAT testing is not a legal obligation. Performing. Anyone with a good knowledge of inspecting electrical equipment can do it. It can be expensive to inspect all the electrical equipment at once and can be time-consuming.

Having someone to inspect any issues in the electrical equipment from your workspace can save both time and money. But, hiring a professional with years of expertise can complete the process in a much shorter period. Besides, they are reliable and efficient. You don’t have to worry about inspecting your electrical system anytime soon.

4. New Equipment Doesn’t Require Inspection for a Couple of Years

It is common for people to believe that new equipment doesn’t need inspection and testing for the first few years. This is also a myth and it can vary depending on the use of the appliance. Faulty parts and chipsets are often found in new electrical appliances as well.

This can affect the performance of your appliance and it must be inspected to sustain further damage. Any tool or appliance can malfunction at any point in time.

There is no binding to whom or when this test must be carried out. Maintaining safety and preventing any danger must be the priority. Until the damage is visible or the device is malfunctioning, the need to perform this test on new appliances is not required.

5. Only Big Companies Need to do this Test

Several small-scale companies and new startups often think of skipping the PAT test. This saves them both time and resources but can put your business at risk. Both big and small corporations must consider testing their appliance at regular intervals.

This will prevent any mishaps or hazards in the workspace and will keep employees safe. There might be some issues that are not visible from the outside but may require a thorough inspection. This applies to big and small companies that depend on electrical equipment to perform daily operations.

The Bottom-line

PAT test is an effective way of mitigating the responsibilities to keep the life of employees safe. It also ensures the proper functioning of your electrical equipment. There is no legal binding to follow any specific rule related to PAT testing. Besides, it is easy to believe in myths, especially the ones that sound real.

These are a few myths about PAT testing that leads to poor judgment while inspecting electrical equipment. Make sure not to believe them and consider doing your research before believing such assumptions. You can consider making rules that work best for your company. This will also help the companies to motivate and influence the performance of the employees.